Types of Compressor Problems

Understanding different compressor failures helps identify the appropriate repair approach and expected costs.

Mechanical Compressor Failures

Seized Compressor: A seized compressor occurs when internal components lock up, preventing the motor from turning. This often results from lack of lubrication, overheating, or contamination within the system.

Worn Compressor Valves: Valve problems reduce compression efficiency, causing poor cooling performance and increased energy consumption. Symptoms include reduced cooling capacity and unusual operating sounds.

Compressor Motor Issues: Motor problems can cause the compressor to fail to start, run intermittently, or draw excessive current leading to electrical problems.

Electrical Compressor Problems

Capacitor Failures: Start and run capacitors provide the electrical boost needed for compressor operation. Failed capacitors prevent the compressor from starting or cause it to run inefficiently.

Electrical Connection Issues: Loose or corroded electrical connections can cause intermittent operation, overheating, and potential safety hazards.

Contactor Problems: Worn contactors may fail to engage properly, preventing the compressor from receiving power or causing electrical arcing.

Refrigerant-Related Issues

Low Refrigerant Levels: Insufficient refrigerant causes the compressor to work harder, potentially leading to overheating and premature failure.

Refrigerant Contamination: Contaminated refrigerant can damage internal compressor components and reduce system efficiency.

System Restrictions: Blocked filters, clogged lines, or restricted expansion valves force the compressor to work against excessive pressure.

Professional Compressor Diagnosis Process

Accurate diagnosis is crucial for effective compressor repair. Our qualified technicians use systematic approaches to identify the root cause of compressor problems.

Comprehensive System Evaluation

Initial Assessment: Our technicians begin with thorough system inspection, evaluating overall condition and identifying obvious problems before focusing on compressor-specific issues.

Electrical Testing: We test all electrical components including capacitors, contactors, and motor windings to identify electrical faults that might affect compressor operation.

Pressure Testing: Comprehensive pressure testing reveals system restrictions, refrigerant levels, and internal compressor condition.

Performance Analysis: We measure system performance including temperature differential, airflow rates, and energy consumption to determine compressor efficiency.

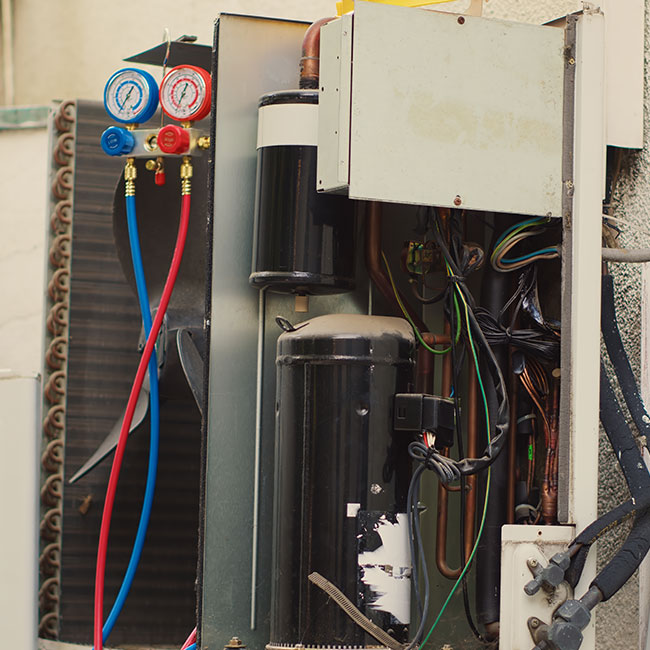

Specialised Diagnostic Equipment

Digital Multimeters: Precise electrical measurements help identify motor problems, capacitor failures, and wiring issues.

Manifold Gauge Sets: Professional gauge sets measure system pressures and help diagnose refrigerant-related compressor problems.

Amp Clamps: Current measurement tools identify motors drawing excessive power or failing to start properly.

Temperature Sensors: Accurate temperature readings help assess compressor performance and system efficiency.

Compressor Repair Solutions

When you choose Vital Air Conditioning Services for aircon repair, you receive comprehensive solutions tailored to your specific compressor problems.

Repair vs Replacement Assessment

Factors Influencing Repair Decisions:

- Age and condition of existing compressor

- Cost of repairs versus replacement

- Warranty coverage and availability

- System compatibility and efficiency considerations

- Long-term reliability expectations

Economic Considerations: Our technicians provide transparent cost analysis, helping you make informed decisions about repair versus replacement based on your specific situation and budget.